Rigging Device Use & Safety

March 28, 2022

After covering the important safety measures necessary for equipment such as cranes, conveyors and slings last month, AMG’s own Don Duval, MDTA Construction Safety Auditor says a discussion on rigging devices must follow! So, today we will talk about the proper use of shackles, hooks, wire rope clips, wedge sockets, eyebolts, spreader beams and sling types of shackles.

Proper Use of Shackles

Types of Shackles

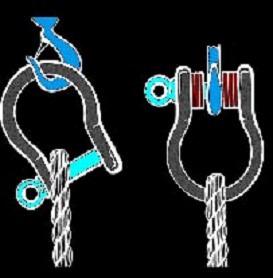

Never replace a shackle pin with a bolt

as the load can bend the bolt as in this illustration.

Check with manufacturer for specifications on Side Loading.

120 degree max.

Avoid eccentric loads.

Incorrect (L) Correct (R)

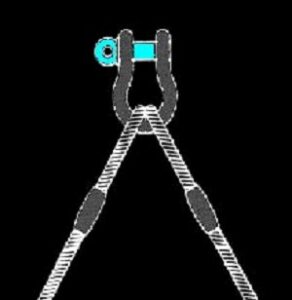

Proper chocking of shackles

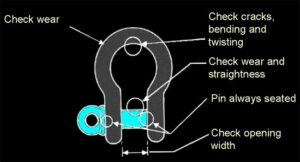

Shackle Inspection

Hooks

Manufacturers’ identification.

Never weld on hooks.

Working safety latch.

Hooks are designed to apply the load at the bottom of the saddle.

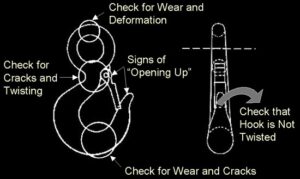

Hook Inspection Items

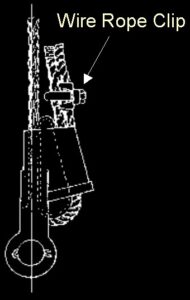

Wire Rope Clips

The most common use of wire rope clips on cranes is at wedge and socket-end fittings.

The clip does not provide strength to the wedge and socket connection.

It is there to prevent the wedge from accidentally being released.

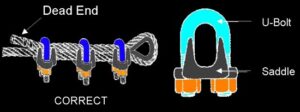

Installing Wire Rope Clips

Installed properly as to number, direction, spacing and torque.

Never saddle a dead horse.

Examples of Improperly Installed Wire Rope Clips

Ladder Inspection Requirements

March 29, 2022

We have touched on ladder safety handling in previous blog posts, but there is so much more to cover when it comes to this critical topic! Each year, there are more than 164,000 emergency room-treated injuries and 300 deaths in the U.S. that are caused by falls from ladders. Most ladder deaths are from falls of 10 feet or less. Falls from ladders are the leading cause of deaths on construction sites. Suffice to say, there is no such thing as overkill, when it comes to implementing and following comprehensive control measures and reducing the potential for fall-related injuries or deaths on the job.

Along with all fall protection equipment, ladders should be inspected regularly to ensure safe use.

Ladders should be inspected immediately after purchase, before and after each use, and before storing to ensure that defective or damaged ladders are removed from the work site.

When inspecting any type of ladder, look for:

- Bowing or warping. Check the rails for any twisting or distortion.

- Corrosion or rust. Check for rot in wooden ladders, and cracks in fiberglass ladders.

- Any signs of excessive wear

- Loose nails or screws

- Loose or missing rungs

- Lack of appropriate labels

- On extension ladders, check joints and locks. All parts should be lubricated appropriately.

Part of ensuring ladder safety on the job site is having a complete ladder safety policy to act as a point of reference for employees and for use during training.

A ladder safety policy should describe in detail the appropriate and expected procedures and guidelines for employees to follow when using, storing, and inspecting ladders. The policy should also state clearly the consequences of failing to comply with these procedures, as well as outline the responsibilities of both the employer and the workers, and the definition of each piece of equipment that will or could be used on the job site.

While some or perhaps all of this information may seem like common sense, the data regarding workplace injury and the incorrect use of ladders and other safety equipment should alert companies to the need for clearly outlined procedures and documentation.

Safety in the workplace is a collective responsibility.

Employers are responsible for ensuring the application of proper policy and routine training for all workers; while workers are responsible for complying with appropriate procedures and safety measures at all times.

What is Materials Handling OSHA?

February 28, 2022

Once again, we reached out to Don Duval, MDTA Construction Safety Auditor for Anthony Management Group, for some safety tips. This month he suggests we reacquaint ourselves with OSHA’s recommendations for Materials Handling and why it so vital to pay attention!

Handling and storing materials involves diverse operations such as hoisting tons of steel with a crane, driving a truck loaded with concrete blocks; carrying bags or materials manually, and stacking palletized bricks or other materials such as drums, barrels, kegs, and lumber.

What is proper material handling?

Avoid lifting materials from the floor or while seated. Make use of available handling aids. Refrain from using sudden or jerky movements. Never lift a load over an obstacle. Perform lifts in areas with adequate footing, space and lighting.

Why material handling is hazardous?

Material handling is accompanied by numerous risks, especially when done manually. Tasks such as lifting, carrying and pushing can make the workplace unsafe for employees. Material handling injuries can also be quite expensive with medical costs, lost productivity and decreased employee morale.

Why safety in material handling is important?

The reason being, a proper materials handling protocol will prevent accidents and improve the efficiency of your facility or construction site. … Whether its maximizing the efficiency of your loading dock or preventing workplace accidents, a proper material handling protocol is key.

What are 4 potential hazards relating to materials handling injuries?

Some of the hazards in material handling include: Workers being hit by materials, caught between them or in pinch points. Exceeding load limits. Falling caused by improperly stored materials. For more detailed information on materials handling safety, see the PDF from OSHA at the link below:

https://www.osha.gov/sites/default/files/publications/osha2236.pdf

Important Safety Measures

February 28, 2022

According to the OSHA manual on Materials Handling and Storage, “To reduce the number of accidents associated with workplace equipment, employers must train employees in the proper use and limitations of the equipment they operate. In addition to powered industrial trucks, this includes knowing how to safely and effectively use equipment such as conveyors, cranes, and slings.”

Cranes:

For cranes, the major types of accidents include contact with power lines, overturns, falls and mechanical failure. Because cranes are hoisting tons of materials such as steel and concrete, they must only be operated by thoroughly trained and competent workers.

Preventing crane hazards includes knowing load specifications, the capacity of the crane and assessing that the job will be safe based on those variables. Always check the crane load chart to avoid exceeding load limits.

Make sure the crane is regularly inspected by a qualified agent anytime that equipment has been modified, repaired or adjusted. Cranes must always be inspected after assembly, and at least once a year – even equipment not regularly in use!

Slings:

The sling connects a crane hook to a load. These must also be property selected and inspected. Reduce sling hazards by providing proper lubrication, keeping clear of the loads, and avoiding sudden movement of the load. Also, never shorting with knots, bolts or other devices or kink the legs.

Forklifts:

Employers are required to comply with all OSHA standards relating to materials handling, including training requirements for forklift training and inspection requirements.

Always comply with any manufacturer’s requirements and recommendations for materials handling equipment. While this is a huge topic, these are just some touchpoints. More information can be found at www.osha.gov.

https://www.osha.gov/sites/default/files/publications/osha2236.pdf

Excavation Safety

Jan. 28, 2022 by Enyinna Anthony, PMP, CCM

The primary hazard of trenching and excavation work is employee injury from a cave-in. Before workers enter a trench, a soil analysis should generally be conducted to determine the appropriate employee protection methods such as sloping, benching, shoring or shielding. Employers should also consider potential struck-by hazards associated with heavy equipment, falling loads and public vehicular traffic in close proximity to the excavation operations. Also consider potential hazards from undermining sidewalks and buildings. Other unsafe conditions that may be encountered include hazardous atmospheres and electrical hazards from overhead and underground power lines. These five key trench safety tips will help keep workers safe:

- Ensure that there’s a safe way to enter and exit.

- Ensure trenches have cave-in protection

- Look for standing water and test if atmospheric hazards are or may be present

- Keep materials away from the edge of the trench

- Never enter a trench unless it has been inspected by a competent person.

For homeowners, they may be many reasons you wish to dig a trench or even dig holes on your property for installing fencing or planting a tree. Before starting any digging or trenching project it is imperative to contact you local Miss Utility so any underground utility lines such as electrical, water, phone or cable, gas, petroleum, sewer or drain, etc. The call and subsequent services are free. While the Miss Utility Call Center does not perform locating or marking services, they inform subscribing facility/utility owners of the proposed excavation so the homeowner does not need each individually. They, in turn, will locate and verify if your site is clear.

Accidentally cutting into a utility line can disrupt vital services or even cause a fatal accident. An average of 54 people die each year from excavation hazards during construction activities according to the U.S. Bureau of Labor Statistics.

https://www.cdc.gov/niosh/docs/wp-solutions/2011-208/pdfs/2011-208.pdf?id=10.26616/NIOSHPUB2011180

What to do in the Case

of a Fall Injury

Jan. 25, 2022 by Enyinna Anthony, PMP, CCM

For last month’s Safety Tips article, we featured a concise list of important things to do and not to do if you want to prevent falls, either on the jobsite or the household. But what do you do if even under the best of circumstance, someone suffers a bad fall?

Jobsite

According to AMG’s Donald Duvall, MDTA Construction Safety Auditor, it is imperative that a person trained in First Aid, CPR and AED is always on a construction site. “Only he or she can administer the proper care for an injured worker,” he warns. “Depending on the injury from the fall such as a broken arm, leg or other bone, or head injury such as a concussion, etc., it’s best to call 911 immediately.”

“Once the injured employee is cared for by the emergency response team and removed from the site, a safety person comes in to start the investigation,” Don explains. It is important to determine exactly what happened, why it happened and decide mitigation strategies to ensure in never happens again.

Photos may be taken of the accident site and potential causes, but absolutely no photos are to be taken of the individual who suffered the injury!

Household

If a family member or guest suffers a serious fall in your home, immediately call 911 to get medical treatment. Try to make the person as calm and comfortable as possible, but do not move him or her. You may even discourage the fall vicitim from twisting or trying to get up and ask him or her to remain as still as possible to avoid exacerbating the injury. Emergency responders are better trained at moving fall victims, so leave it to the experts. If necessary, try to control any bleeding by applying pressure and a clean bandage. If the person is unconscious, check for any breathing obstructions. If the fall was outside, such as on a patch of ice, provide extra blankets or other coverings to keep that person warm until emergency responders arrive.

If a fall does not need medical attention, it is still prudent to ask the person to move slowly and carefully. Watch for bruising or swelling and provide a wrapped ice pack for any area that begins to show these signs. Do not apply ice directly to bare skin.

Both shock and the body’s ability to create endorphins upon injury can sometimes mask the pain of a break or bad sprain, so continue to observe the injury and, if necessary, take the person to the ER or urgent care doctor to be on the safe side.

More Quick Tips on Fall Protection

Dec. 29, 2021 by Enyinna Anthony, PMP, CCM

- Identify all potential tripping hazards and fall hazards before work starts.

- Look for fall hazards such as unprotected floor openings/edges, shafts, skylights, stairwells, and roof openings/edges.

- Inspect fall protection equipment appropriate for task.

- Secure and stabilize all ladders before climbing them.

- Never stand on the top rung/step of a ladder.

- Use handrails when you go up and down stairs.

- Practice good housekeeping! Keep cords, welding leads and air hoses out of walkways or adjacent work areas.

Sadly, in 2019, 880 workers died in falls and 244,000 were injured badly enough to require days off from work. It’s important to realize that a worker doesn’t have to fall level to suffer fatal injuries.

The Importance of Inspecting Smoke Detectors & Alarms

Dec. 29, 2021 by Enyinna Anthony, PMP, CCM

When jotting down those New Year’s resolutions, make sure you place the job of habitually inspecting your smoke detectors and fire alarms on a regular basis.

Donald Duvall, MDTA Construction Safety Auditor for AMG says, “smoke detectors should be inspected every year.” He cites that the National Fire Protection Agency (NFPA) suggest January inspections as it’s the first of the year.

Smoke alarms were present in three-quarters (74 percent) of reported home fires in 2014-2018 and almost three out five home fire deaths were caused by fires in properties with no smoke alarms (41 percent) or smoke alarms that failed to operate (16 percent).

“When smoke alarms were present in reported fires considered large enough to activate them, they operated 89 percent of the fires, 73 percent of the deaths and 82 percent of the injuries,” Says Don, “However, the risk of dying in reported home structure fires is 55 percent lower in homes with smoke alarms than in homes with no alarms or none that worked.”

AMG would like to remind you to please inspect your home smoke alarms. We want safety to be everyone’s top resolution this year and every year. For more information, NFPA offers this Smoke Alarm Safety Tip Sheet you can download and print.

Taking Ladder Safety One Step at a Time

Oct. 1, 2021 by Enyinna Anthony, PMP, CCM

Cleaning leaves out of gutters, putting up Halloween decorations or stringing up Christmas lights are looming tasks for many homeowners in the months ahead, but falling from a ladder can cause serious injury or even death. So, when it comes to ladder safety, it’s best to take advice from professionals in the construction industry before stepping on the first rung.

Donald Duvall, MDTA Construction Safety Auditor for AMG says its important to have the right kind of ladder for the job. For instance, when cleaning gutters, one would typically use an extension ladder. “Make sure the ladder extends to a minimum of three feet above the gutter, he says. Tie and secure the ladder in such a way that it won’t be able to slide sideways if you are reaching and shift weight too much to one side. For this reason, it’s also advisable to have someone hold the ladder at the bottom to help keep it steady.

Ladders must also be kept clean and dry to prevent the user from slipping. On the jobsite, ladders are inspected before use to ensure they are free from any mud, grease or cement. Standing on the top cap of an A-frame/stepladder is forbidden on the jobsite as it’s too unstable – a good rule for use in the home as well.

Ladders should also be made from non-conductive materials. This is usually fiberglass, but in some cases might be wood. “Homeowners often have aluminum extension ladders,” Don notes, “as they are less expensive and lighter to carry, but fiberglass ladders are made for a reason.” An aluminum ladder accidentally coming into contact with anything electrical can have devastating consequences. Never handle ladders of any kind around powerlines.

Finally, always make sure you are adhering to the weight restrictions of your ladder. Most household ladders are considered light duty and have a maximum of 200 lbs.

For more suggestions, OSHA offers an easy-to-follow Ladder Safety Quickcard you can download and print.

Autumn Slip, Trip & Fall Prevention Tips

Oct. 1, 2021 by Enyinna Anthony, PMP, CCM

No doubt, October is the month most recognized for the days growing shorter, leaves changing spectacular colors and the fragrance of wood smoke and pumpkin spice filling the air, but unfortunately, once those autumn leaves waft downwards, they add a more dangerous dimension to this time a year… maybe that’s why it’s also called Fall!

Donald Duvall, MDTA Construction Safety Auditor for AMG warns that once leaves start falling, especially combined with rain, roads and driveways get slippery both on the jobsite and the home front. “Mud can also be an issue,” he says, “This is the time we notice the crew cleaning mud from boots, ladders and other equipment to prevent possible slipping and falling.”

As a safety auditor, Don takes any potential for slipping and falling very seriously. Falling can result in anything from a sprained wrist, broken leg or other injury. “Sometimes people will try and take a short-cut by going off the usual path on the construction site, but you have to be careful going down slopes that have become slippery from fall weather.” For this reason, he cautions against taking any short cuts.

Frozen surfaces are another hazard that appears as the temperatures drop. People are on the job early in the morning before the sun has had a chance to warm up the asphalt. He’s witnessed such falls on the site that caused injuries. “Anytime it gets below freezing, you have to be careful of the black ice,” he warns. “Sometimes it’s nearly invisible.”

“Now is the time to start preparing for the rest of winter,” Don advises, “such as identifying hazards, making sure rock salt is readily available and everyone is wearing the correct footwear. It’s important to provide proper lighting, signage, good housekeeping protocols and slip-trip-fall training for the entire staff.

According to the Occupational Safety and Health Administration (OSHA), slips and falls are the second major cause of death in the US. Slips, trips, and falls are also the second most common cause of injury at work and 20-30% of falls that occur in the workplace lead to moderate to severe injuries such as bruising, fractures or a concussion.

For more tips and information about fall prevention, visit Slips, Trips and falls: Protecting Your Employees from Preventable Injuries.

Walkway Collapse in Ellicott City

Aug. 8, 2019 by Enyinna Anthony, PMP, CCM

When I read the news about yesterday’s walkway collapse in Ellicott City, I couldn’t help but feel the mixed emotions of sorrow, shock, gratitude and fear.

I felt sorrow for the person who was injured. I felt shock that something like this could even happen. There was gratitude that not more people were hurt, and that no loss of life was suffered by the injured party, as I know all too well that this can happen. And finally, I felt fear, because with all the construction work, building, bridge and roadway repairs that go on every day, what are the chances that something like this could happen again with even more disastrous results?

As an engineer, the wonder of a city skyline never escapes me because in my field of expertise and education, I know just how much science, planning and labor go into constructing one bridge, more or less an entire metropolis of structures that, for better or for worse, we tend to take for granted every single day.

It’s for this reason that safety and quality control became one of the key focuses of my business. In a world of construction, when a million things can go wrong, we must make every effort to ensure that the things that go right are the protection and safety of not only our citizens, but the workers building these engineering feats.

There is not enough information reported for me to even begin to speculate as to how this might have happened, but my thoughts and prayers go out to the individual who was injured yesterday in this incident.

I take it as a reminder that we have moral duty to take proper due diligence in every phase of the construction life cycle and conduct each of the jobs we do with the utmost integrity.

https://patch.com/maryland/ellicottcity/walkway-collapses-ellicott-city-building-officials-say